Hello everyone!

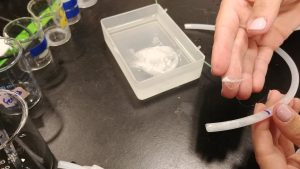

This week was a great week in the N.E.W.T. lab at ASU! I ran my final test on my mini column system with the 2 SIAC GAC media, my impregnated F400 GAC, Clemson’s CU #2, GAC blank, and zeolite blank. If you have been following my posts, you will remember that Clemson’s CU #2 is my nemesis and was very difficult to get water to flow threw it. Well, this week I tested with 90% diluted tap water spiked with 250 ppb bromide and the CU#2 worked! I could get water to flow through all six of my columns for the first time this summer! It was so beautiful. I will be very curious to see the bromide results from this run.

Now that I am done running my tests, I have focused my time on creating my poster and the presentation I had to do for my PI on my research. It was a little intimidating getting up and talking in from of these professors, doctoral students, and graduate students. My mentor said I did very well and I didn’t get many questions at the end so I call that a success! My poster was actually a lot of fun to make. I have been teaching my students for years how to make a scientific poster, but I have never made on myself until now. I was worried because I was only able to get one of my tests analyzed because we are waiting on a silver guard and we were short on people who were properly trained and had time to run samples for me. A shout out to Choa Zeng for helping me out and analyzing at least 27 samples for me so I had something to talk about on my poster. The results showed that the SIAC 4% GAC and the CU#1 media could remove bromide, but only for a small bed volume (400 BV and 100BV). What was surprising about the data was that the GAC blank also removed bromide from the samples. I am looking forward to getting the characterization information back about that media to see if there is something that could help explain that result better.

I am glad to be done with my poster though and can’t wait to share it with everyone next week at Rice University!

Have a good weekend!

-Taylor