NEWT RET Week 3 Blog Tom Geiss

I began my week in the lab assisting Marina Marcos and Roy Arietta in preparing composite nanomaterials for an experiment to test the composite materials ability to adsorb Arsenic from a simulated fresh water sample with an Arsenic Concentration of 50 ppb. Just a reminder, the composite material is made of three different nanomaterials: graphene, iron oxide and Zinc ZIF. Last Friday, we prepared our NEWT fresh water sample using the NEWT recipe. We did everything except add the Arsenic to the NEWT fresh water solution.

Making the NEWT Fresh water can be a little challenging as some of the masses can be very small. Below is a photo of one of the salts we add to the solution as it sits on the scale. As you can see the mass (0.00072 g) is one tiny spec of the salt.

The next step was to measure different masses of the composite nanomaterial. We measure out 10 different masses ranging from 0.000125 g to 3 grams. On two different masses we measure duplicate masses so that we can verify the validity of the test data.

After the all of the masses of the composite materials were measured we then buffered the samples with Sodium Bicarbonate. We let the different masses soak overnight. The next day we used a pH meter to record the pH and confirm they were within an acceptable range. After recording the pH we rinsed the samples in DI water. That’s when we realized we had a problem. While rinsing and decanting we saw we were losing small amounts of mass of each different sample as we were decanting. We tried to compensate by using a magnet (my idea) while decanting but we still lost material in the process. This meant that the masses we recorded at the beginning of the experiment would not be valid.

Marina and Roy being much brighter than I, quickly came up with a solution. Not a new solution of composite but a new solution to the problem. They concluded the answer was to create additional composite material buffered in sodium bicarbonate, then create 10 new samples of composite that had been buffered and cleaned. That way the masses stay consistent throughout the experiment.

So by late Thusday or Friday we can continue our experiment with adsorption of 50 ppb of arsenic.

While were measuring our masses and preparing our samples, discussion turned to the diversity training we had attended on Monday. Mariana asked what I thought about the training. What ensued was a thoughtful discussion of how diversity is addressed in academia, business, middle school, and high school. I shared that I thought that among my peers that I teach with diversity is accepted and valued. I also thought that people still had perceptions based upon stereotypes that might be expressed in nuanced ways. Mariana shared a story about being in a food court and an acquaintance expressed surprise at her choice of food thinking she might chose a food that was more culturally relevant to her. It surprised her that someone would assume that based upon her ethnicity she only eats a certain type of food.

I have been thinking a lot about the TED talk we watched last week about “The Danger of Single Story” by Chimamanda Ngozi Adichie. I have thought about this in a few ways. One, I think about how I make assumptions about what types of activities they can and can’t do in a lab setting. Or how I may have preconceptions about their reading or math ability that may not be true. Even when we engage in “data mining” based upon STAR practice tests, it doesn’t tell the whole story of that student’s ability or even their real reading level. Some of my students according to the data are 8th graders that read at the 2nd grade level. However, when reading aloud in class they clearly have a higher comprehension of what they read, than what their test scores reveal. Reason being, they tanked the test on purpose because they did not care about the outcome.

I have also been thinking about how close minded my students are of anyone who is slightly different than they are. My students are predominantly Hispanic males between the ages of 12 and 15. They are dismissive of anyone who does not look like them, act like them, like the same music as them, does not talk like them, does not like the same food as them, etc. etc. I know some of this is part of adolescence, but the intolerance as such a young age is depressing.

How do you get that close minded at such a young age? My stepfather was a closet racist. He worked in a culturally diverse work place. When he came home he made derogatory comments about people of different ethnic and religious backgrounds that I am sure he did not share at work. Rather than parrot these ideas, I compared his observations with the children I went to school with. I grew up in Topeka Kansas. Home if the famous Brown vs Board of Education. That Supreme Court case was decided in 1954. By 1965 when I started school, we had a diverse student population. In my observations the children of color were no different than me. We all wore pretty much the same clothes, ate the same food, listened to the same varieties of music and played and learned together with the same peaks and valleys. So I quickly decided my step father was full of it and tuned him out when he went on his racist rants at home.

So I am really discouraged that 40 plus years after I attended middle school, in some ways we have gone backwards in time. During the Diversity seminar on Monday, a participant at another location stated that they thought that social and emotional learning was key to getting students to accept and respect diversity. I totally agree. We have started using circles at our campus to address social and emotional issues and build relationships between student and staff. Success has been limited, but I am optimistic.

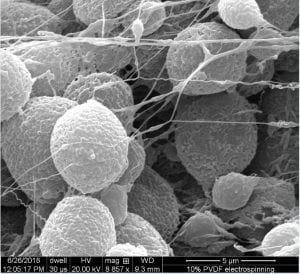

On Wednesday we started synthesizing started nanomaterials for adsorption tests we will start We began on Friday. The first material we created was Zinc ZIF. We are going to test the adsorption rate of the Zinc ZIF so that we have a comparison to the adsorption rate of the composite material which has all 3 nanomaterials in it.

Once we have added Arsenic to our NEWT water we will put 500 mL of contaminated NWT water in 14 jars. One jar has no nanomaterial to serve as a control and the others have various amounts of nanomaterial.

Then for three days we put the jars in a shaker that slowly moves the jars in a circular motion. This allows the nanomaterials to be moved in solution with the contaminated NEWT water.

We ran into a problem with our NEWT water. I made a bone head move and did not make a correct calculation on one of the compounds you make NEWT water with. My error in calculation, ( I forgot to divide by 1,000) which made me add 1,000 times more Sodium Phosphate than was needed for experiment.

Marina told me this happens to everyone so don’t get too upset. So we tossed the contaminated water with arsenic down the drain and started again. Just kidding. There was no arsenic in it so we didn’t contaminate the El Paso water system.

Once the NEWT water was done and we had all of our different masses of nanomaterials weighed out. We put all 27 of our samples in the shaker at set the motion at 100 rpm (see photo below). We have 13 composite samples and 13 ZIF samples and 1 control. We will take them out of the shaker on Monday afternoon and then begin to prepare them for analysis to see how much Arsenic was removed from the solutions.

That’s all for now. Next week we get into some real Rick and Morty stuff. See you then!