The first week of the NEWT RET internship has been both the shortest and longest week that I have had in a long time. My experience so far has been a flashback of my days in graduate school which included long days filled with classes, reading scientific articles, trying out procedures in the laboratory and running on caffeine. This week has included all of those things and more.

During the first meeting with my mentor and PI I was introduced to a new scientific approach which includes 4 basic steps when developing a research program. These steps included identifying a need, developing an approach to met that need, analyzing the benefits of your research and reviewing current end products by competitors. Such an easy approach but it made me think of research in a whole new light. It also gave me a new approach to share with my students! From that conversation my PI encouraged me to develop project ideas that I was passionate about and so the work began.

The ideas that I had brainstormed oddly enough stemmed from the environmental science class that I teach vs. my biology course (which is the main component of my teaching). I toyed around with a variety of ideas from breaking down plastics in water sources, to treating water sources at dairies to researching ideas concerning deadly algae blooms. When conducting my research I found that the breaking down of plastics, which I thought was going to be “THE ONE”, was not as interesting as I had hoped. Instead as I continued my research I began to find a link between toxic algae and dairy farms and so began the look into algae. When I presented the algae idea to the PI he was excited, first asking though if I would be passionate about the idea. Oddly enough I found myself smiling and shaking my head and now, I am all about algae. :0)

The idea now? To see the effects of paint containing titanium dioxide in reducing the growth of algae. Why algae? Algae I found is not only harmful to fish, but is also harmful to a variety of other organisms including cattle and even humans. Plus, algae can just be unappealing in a variety of water sources including fish tanks, man made water structures (such as those in golf courses and residential areas) and pools.

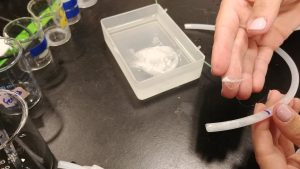

My next steps are to now become familiar with growing algae in the lab and to see the research that exists on treating algae with nanoparticles. Hopefully by doing so formulate a research plan including titanium dioxide in reducing the growth of algae.

The first week of NEWT RET has been the shortest and longest week and it has been a stressful and tiring week of finding my place in the world of nanotechnology. It has also been a week of laughter, comradery, caffeine and pushing myself beyond self imposed limits.

So, in a nut shell, what I have learned this week can boil down to the following:

*Collaboration is key.

* Blessed are those who are flexible, for they will never be bent out of shape.

*Try, try and try again.

…and lastly, but perhaps most importantly… Let’s create an innovation!