UTEP Newt

My first week of NEWT at UTEP was one of shock and awe. I was shocked by how much I didn’t know about chemistry and I am in awe of the people in the group I have been assigned too. Their knowledge of inorganic chemistry and their patience with me is truly amazing.

I have been assigned to Dr. Dino Villagran at UTEP and I am working with his graduate student Mariana Marcos. I told Dr. Dino right away that I was a little concerned about my current level of understanding of chemistry. He graciously offered to let me sit in on his General Chemistry class that he is teaching at summer school. So almost every day this week my day has started at 8:00 AM with 150 other students in an auditorium. Boy have things changed since I took chemistry in college. When I took chemistry back when I was in college, there were only 40 elements on the periodic table of elements.

After chemistry class I head over to the lab. My mentor, Mariana Marcos is doing research on using nanomaterials to remove Arsenic from drinking water. The nano-materials that we will be working with and actually synthesizing are: graphene oxide (GO), magnetite (Fe3O4), and zeolitic imidazolate frameworks (ZIF).

Each of these three materials has shown selectivity in adsorption of arsenic in simulated drinking water. The objective of the project is to obtain and compare the adsorption capacity at 5 and 50 PPB (As) and determine the selectivity of each of the three composite nano-materials towards Arsenic.

Mariana gave me an article on removal of Arsenic from water titled: “Technologies for Arsenic Removal from Water: Current Status and Future Perspectives”, from the International Journal of Environmental Research and Public Health. The introduction of the article provided background of Arsenic as a pollutant in drinking water. Not only is Arsenic introduced to the environment via agriculture and various industrial uses, it is also introduced through natural sources such as the weathering of rocks which contain arsenic. I learned that Arsenic is a naturally occurring metalloid that that is very “mobile” in the environment based upon its parent mineral form, oxidation state, and mobilization mechanisms.

Based upon oxidation state, arsenic can exist in 4 forms. Of these 4 forms of arsenic the most prevalent forms found in water are arsenite (As (III)), and arsenate (As(V)), which are both inorganic.

Arsenic is known to be a highly toxic to all life forms and is classified as a group one carcinogenic substance by the World Health Organization. The WHO has stated that arsenic concentrations in ground water should be limited to no higher than 10 µg/L. At levels above 50 µg/L in drinking water, people can develop a wide range of health problems including cancers. Collectively these disorders are referred to as arsenicosis. According to the article I read, the ground water contamination for arsenic is highest in Asian countries. In Bangladesh and India over 120 million people are exposed to contaminated ground water with above 50 µg/L. In Bangladesh, the arsenic level in some tube wells is as high as 4730 µg/L.

According to this article arsenic in its most common form arsenic can be difficult to remove because of its oxidation state. Typical water treatment methods for arsenic involve a two-step process for removal. First the oxidation of soluble arsenite to arsenate. After that, a removal technique must be used such as adsorption, coagulation, or ion exchange. According to the article, oxidation can be problematic as other contaminants in the water can interfere with the oxidation process.

So this is where nano-materials come in to save the day. Research has shown that iron oxide nano-materials have been five to ten times more effective in the removal of arsenic that conventional water treatment methodologies. Mainly because of their high surface-to-volume ratios. Plus, their magnetic properties make extraction from the water easier using magnets.

So this week I started in the lab helping Mariana Marcos synthesize some Fe304 nano-particles. You do this by a process called co-precipitation. I don’t need to tell you guys that iron (Fe) exists in 2 oxidation states. So co-precipitation calls for using Fe3+ and Fe2+ ions in a 2 to 1 molar ratio. So a sample is prepared using 2 moles of FeCl3 and 1 mole of FeCl2. Then 100 ml of DI water is added. Then you heat the mixture to 85 degrees Celsius while stirring in a N2 environment. After the temperature is reached you introduce 12 ml of NH4OH. This reaction then yields the Fe304 nano-particles.

After the solution is cooled down to room temperature it is washed twice with DI water and then sonicated.

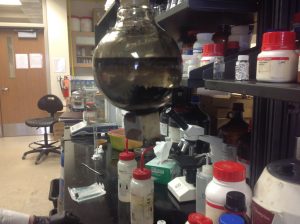

The picture below shows how the nano-particles as it looked while it was cooling to RT.

As the solution was cooling we placed a magnet at the bottom of the flask to migrate the Fe304 nanoparticles to the bottom. This photo shows them before sonicating.

The next picture shows the nano-particles after they have been washed twice and sonicated.

The black residue at the bottom are the Fe04 nanoparticles which were then dried in a vacuum over-night.

On this particular batch, Mariana reduced the volume of reactants to see if the resultant nano-particles would be less aggregated. She is looking to see if this change will result in greater surface volume. We will take samples of two different preparations and then look at images of them in a scanning electron microscope (SEM) to see if there is an advantage to using smaller volumes of reactant.

I can’t say enough how helpful my mentors Mariana and Dr. Dino are. They have both taken a keen interest in the lesson I am preparing and I am looking forward to collaborating with them on this project.