Hello everyone!

My name is Taylor Miller and I am a RET intern in the NEWT lab at ASU. I am working in Dr. Westerhoff’s lab with my mentor Shahnawaz Sihna. The focus of my internship is removing harmful bromides that are created through the process of chlorinating water. Disinfectant By Products (DBPs) such as brominated DBPs are extremely hard to get out of our water and my lab is trying to remove them by adding silver nanoparticles to a common cleaning media and new medias that were created by Clemsen. We are putting the media with the silver nanoparticles in a column and adding water contaminated with bromide. If everything works correctly, the silver will attach to the bromide and we will be able to have DBP free water!

The first step in this process was testing to see if the column system Shahnawaz built actually works. I don’t have much engineering experience, but I feel like an engineer after this week. The system was one leak after another. Once I would get it to stop leaking, I had to make sure the flow was the same for the 6 different columns all the while keeping the PSI as close to zero. Sounds difficult, but it was actually pretty easy once I figured out how to control the motor and flow valve.

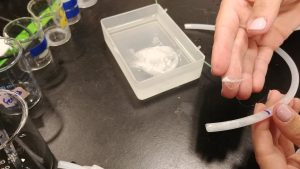

Next step was packing the column. This hasn’t been done before and the column are only .4 centimeters in diameter so I didn’t have much area to work with. I loaded the columns with 2 in. of glass wool to make sure that the media would not go through the column. The columns had great flow when I tested them with the glass wool. I can’t say the same for when I added the media. The media we were practicing with this week was Granular Activated Carbon (GAC). The GAC was tricky to figure out how to get into the column. The first problem we ran into was how to get the GAC all the way down the tube. Dry loading the GAC didn’t work because it would stick to sides of the tube and there were a lot of air bubbles. I decided to add some water and then add the GAC. The wet load worked and the GAC loaded with hardly any bubbles.

The moment of truth came when I had to test the columns with water. It worked the first day with 3 columns, but not the next day. I could get a single column to get water to flow through it. back to the drawing board. I realized that the downward flow of the water into the column was causing bubbles and the media was being compressed from the pressure. After talking to another scientist, Paul, we were able to reverse the flow so the water would go up the column and I could control the flow before it entered the column, not after. Success! Well sort of…

One of my columns didn’t work after a while and will be remaking it again next week. Also, there were more leaks. On a brighter note, I just found out from my PI that I can use some pumps that another lab was using. Hopefully by having each column have its own pump I will be able to see water flow easily through each column.

I am having a great time in my lab and am putting together a great lesson for students to learn about this process!

Until next week,

Taylor

Nice job problem solving and identifying what is causing the hiccup in those tubes!

Thank you Anna! Still have some solving to do. It’s not the easiest system to work with because everything is so small, but I know I can do it!